Parmigiano Reggiano is a name so deeply connected with the best of Italian food. Its sharp yet sweet flavors have won over the world and a true piece of Parmigiano Reggiano Dop cannot be confounded with any other. Yet, stop and consider for a moment what it takes to assure the quality of each piece of this cheese exported to millions of consumers worldwide.

To begin with, what exactly do those three letters ‘Dop’ mean and why are they important when it comes to this king of Italian cheeses? Dop stands for Denominazione di Origine Protetta or translated ‘Protected Designation of Origin’. When a product is certified Dop the consumer can be sure that the product is both produced and packaged locally by local farmers and artisans. By law this also means that a food can be labeled as ‘traditional’ because certification ensures that producers follow traditional preparation methods.

The Guardian of Parmigiano Reggiano

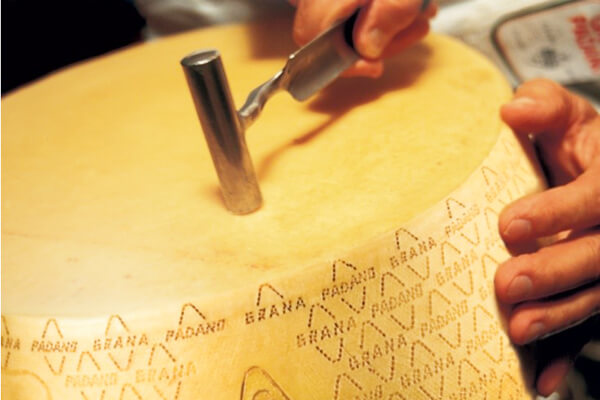

The guardian of Parmigiano Reggiano Dop is the battitore… the person responsible for guaranteeing the quality of each and every cheese produced and sold. A small hammer, a needle and a wedge are the only instruments used by master battitore – literally translated as a batter, who in a few quick seconds test that each individual wheel of cheese is up to standards. However, not all cuts turn out perfectly and about 10-15% of the Parmigiano produced and prepared for sale never actually make it to market simply because Parmigiano is an art… a perfect one.

The battitore plays one of the most important roles in guaranteeing the excellence of Parmigiano cheese. It is he who is responsible for assuring that every wedge lives up to the standards the world has come to expect from one of the most well-known and loved cheeses.

The battitore plays one of the most important roles in guaranteeing the excellence of Parmigiano cheese. It is he who is responsible for assuring that every wedge lives up to the standards the world has come to expect from one of the most well-known and loved cheeses.

The battitore must have a firm knowledge of the product, the cheese making process and even what the cows are fed, and he must combine this knowledge with his experience and in particular with his fine sense of touch, a good ear, and excellent sense of smell, for it is these talents which allow him to examine an average of 1500 wheels of Parmigiano, about one wheel every six seconds.

It is only after the battitore has declared that a single form has reached the standards that it can be classified Parmigiano Reggiano Dop – a large responsibility considering that each wheel is worth about 400 euros but most of all it is his final word which guarantees each consumer that the product they’re buying is truly the best it can be.

It is the battitore of the Parmigiano Reggiano who in just six or seven seconds decides if a wheel of cheese will become Parmigiano Reggiano Dop or not. Each cheese form ends up in one of three categories. The first and top category is called classico. Classico is the best and is the one that is eventually sold in stores and supermarkets around Italy and the world.

It is the battitore of the Parmigiano Reggiano who in just six or seven seconds decides if a wheel of cheese will become Parmigiano Reggiano Dop or not. Each cheese form ends up in one of three categories. The first and top category is called classico. Classico is the best and is the one that is eventually sold in stores and supermarkets around Italy and the world.

The next category is called mezzano. Mezzano, though possessing both the perfect flavors and aromas, are wheels which have a fine line or crack running through them, and are used for grating. The last category is the scartone, discarded pieces. These wheels have some white areas as a result of their aging process. The label Parmigiano Reggiano is removed and the cheese is sold as simple table cheese.

So what is the battitore specifically looking for when he inspects each piece of cheese? Well, that’s easy… perfection, and there is a mandatory expert process specified by all producers that must be followed to assure this. Parmigiano Reggiano is an aged cheese and can only be considered ready for inspection by a battitore after a minimum of 12 months of aging.

The first step is for the battitore to touch the cheese and knock on it with a small hammer for about six or seven seconds – about 20 knocks. If the sound is uniform throughout the wheel it means that it is solid and homogeneous and will therefore be without any defects for either taste or smell. At this point, the cheese is declared up to quality standards and can be fire-branded with the indelible Parmigiano Reggiano Dop label.

However, not all wheels pass the first sound test. If the battitore hears a sound that is described as a low thud or dry (secco), it’s a sign that the inside of the wheel might present imperfections. One possible imperfection is called an occhiatura (‘eye’ in Italian) caused by the presence of a bacteria. Another type of imperfection is referred to as strappi (tears) which are the result of acidity within the cheese that prevent it from aging properly. Finally, a third possible defect is known as the macchie scure (dark spots). These can even be evident on the surface of the cheese and are a sign that the cheese didn’t dry properly.

After any of these defects have been found, the wheel is tested further. However, it’s important that as few holes as possible be made in the cheese since each hole represents a possible entry point for bacteria. The next step in the inspection process is then the spillatura – spillo meaning needle. A needle is inserted to test both the consistency of the cheese and its aroma. The consistency and aroma are important for verifying the cheese’s aging and any eventual defects. Finally, if any doubts remain as to the quality of the cheese the last step is the tassellatura or wedging in which a piece of the cheese is extracted with a special tool.

The battitore is an expert… an artist of sorts you might add. He is to Italian cheese what a sommelier is to wine. And they don’t exist solely for Parmigiano Reggiano but also for other Italian cheeses such as Grana Padano, Lodigiano, Formaggio Piemonte and others.

So how does one become a battitore? Is it something you can study? A secret handed down from one generation to another? Well, the answer is a little yes and no to both questions. The battitore learns his trade hands on by working with the cheese over a period of time. Those already working in the sector have an advantage that those coming from outside obviously do not, and in the past all battitori were retired cheese makers or those who had worked in the craft for a minimum of 10 years.

Today’s battitori do study but it is the mandatory four years as a sort of apprentice working side-by-side with an expert learning all of the subtle nuances of taste and smell that make an expert battitore. Slowly they absorb and unravel the secrets of a trade still to this day handed down from one generation to the next out of a pure passion for a product equal to none and symbolic of the excellence that made in Italy truly signifies.

Photo credits: Parmigiano Reggiano